In- Transit Fumigation

In-Transit fumigation of a cargo is a means of complying with the phytosanitary requirements to prevent the spread of pests and insects. For commercial reasons In-Transit fumigation may be utilized to prevent infestation and contamination of, or damage to, cargoes of human and animal grade foodstuffs.

In Transit Vessel fumigation takes place when bulk cargoes are fumigated on board while in-transit from the load port to the discharge port utilizing the transit time. Triton Fumigation LLC has fumigated millions of tons of wheat, corn, soybeans, rice and other agricultural commodities and by products. Our Licensed Applicators are experienced and well trained in following all Federal, State, and local regulations.

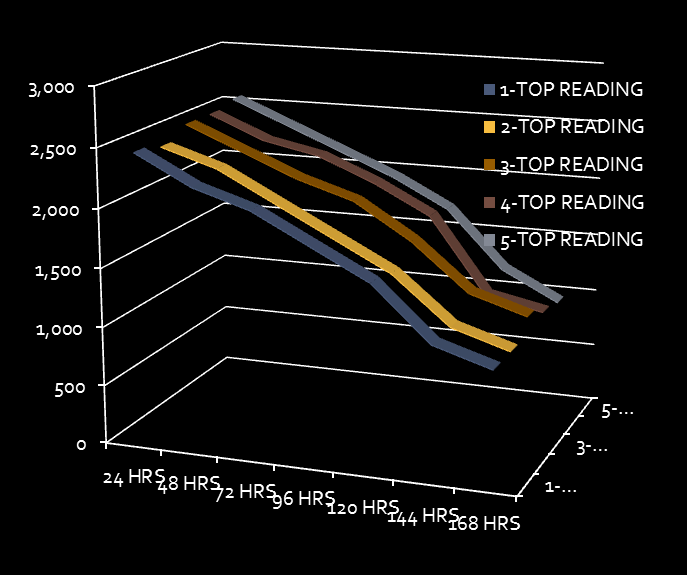

Monitoring In Transit Ship Fumigation

Triton Fumigation Licensed Applicators accompany vessels and monitor fumigant concentrations inside the cargo holds on a routine schedule throughout the exposure period.

Monitoring the fumigant levels inside the cargo holds will ensure that an effective concentration of fumigant at a given temperature, for a sufficient period of time, will kill any live infestations. Both the time measured in (hours or days) of exposure is critical to fumigation efficiency. Having our licensed applicator accompany, the vessel to it's destination will ensure that all aspects of fumigation from application to aeration are done in safe and appropriate manner.

Structural Fumigation

Structural fumigation is a pest control method that involves filling the airspace within a structure with a toxic gas. The structure is sealed with plastic, tarp, or tent to trap the gas inside. During structural fumigations, the interior areas are monitored remotely with specialized gas detection equipment to ensure that fumigant levels reach the required concentration. This allows licensed fumigators to characterize gas concentrations throughout the structure to assist in determining if additional gas is required to obtain the necessary ounce per hour accumulations to kill all life stages of targeted pests.

All structural fumigations include a Fumigation Management Plan (FMP), an organized, written description of the required steps involved to help ensure a safe, legal and effective fumigation. We perform all structure preparations, including identification of pest, selection of fumigants, site- specific safety plans, application techniques, monitoring and ventilation procedures. With more than 80 years experience we are proficient in performing safe and effective structural fumigations in rice mills, flour mills, pet food mills, grain storage facilities, and bins and providing high quality service to our clients.

Commodity Fumigation

Triton Fumigation, LLC Licensed Applicators apply restricted use fumigants to raw & finished agricultural commodities to barges, rail cars, and containers, to control insect infestations.

Fogging

For control of insects such as indian meal moth, red flour beetle, confused flour beetle, saw-toothed grain beetle, merchant grain beetle, cigarette beetle, drugstore beetle, and granary weevil for use in warehouses, silos, bulk bins and food/feed processing, food/feed manufacturing, handling and storage plants.

Mold & Salmonella Applications

Triton Fumigation applies mold and salmonella inhibitors to the grain feed as it is transferred to vessels. The application rate is monitored and adjusted throughout the loading process. The loading facility’s conveyor belt system contains multiple transition points that provide mixing and blending of the treated product to assure an even distribution of mold or Salmonella products.

Mold Inhibitor Treatment

Mold inhibitor treatment products are a blend of organic acids formulated to inhibit mold growth in processed feed ingredients, complete feed and total mixed rations. These products contain propionic acid, blended with sorbic and benzoic acids and buffered for improved equipment and employee safety. Common molds - aspergillus, penicillium and fusarium - infiltrate bins and feeders and rob grain of energy, vitamins and amino acids. Before you realize a problem exists, molds left unchecked can produce mycotoxins, namely aflatoxin, T-2 toxin and zearalenone. Moldy grain costs money, time and productivity.

Description Features- A combination of organic acids with proven anti-mold activity

- Has high PMIE (Propionic acid Mold Inhibition Equivalent)

- Has sustained release excipients

- Has corrosion and pungency retardants

- Inhibits a wide range of molds

- Controls molds immediately on addition and over long periods of storage

- Prevents loss of nutrient and preserves nutrient profile of feeds

- Increases storage life of feed

- Minimizes mycotoxin production

- Improves palatability of feed and thereby animal performance

- Minimizes dustiness, discoloration and building up of heat in feed

- Has minimal corrosive effects and is user friendly

- Free from toxicity at recommended levels, easily available and economical in use

Salmonella Treatment

is a feed-active, resistance-free broad spectrum anti-microbial developed by design of research to control the microbial load of feed and raw materials.

Features

- Synergistic combination of various feed-active organic acids with broad spectrum antimicrobial activity

- Exerts non-specific kill kinetics

- Stable at pelleting temperatures

- Non-toxic and non-corrosive

Benefits

- Inhibits and controls microbial load in feed and raw materials

- Proven efficacy against Salmonella, E. coli, and other common microorganisms in feed and raw materials

- Effective tool for Salmonella control program

- Minimizes shedding of Salmonella and other microorganisms in droppings and improves microbial quality of litter/cage

- Prevents horizontal spread of Salmonella

- Improves hatchability and minimizes early chick mortality in birds

- Does not induce microbial resistance

- Prevents recontamination of feed and raw materials by microorganisms

- Helps disinfect blind spots in feed mill and improve feed mill hygiene

- Minimizes farm losses due to microbial infections

- Controls molds in feed and raw materials

- No residual effect or feed withdrawal periods

- Safe for use in all life stages of poultry